Eco-Genie: Intelligent Automated Recycling System

Project Summary

Eco-Genie is an in-home automated recycling sorter that identifies and routes plastics, glass, and aluminum. The system combines ultrasonic, inductive, and capacitive sensors with a linear-actuated tipping vessel to classify items and drop them into dedicated bins, reducing contamination and the burden of manual sorting.

My Role

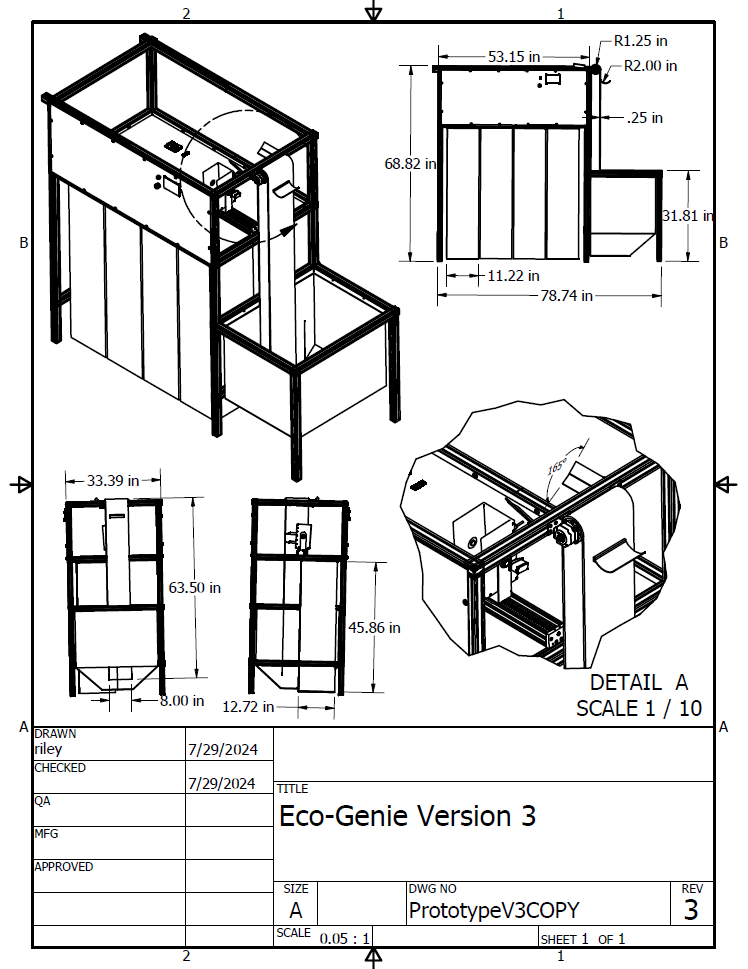

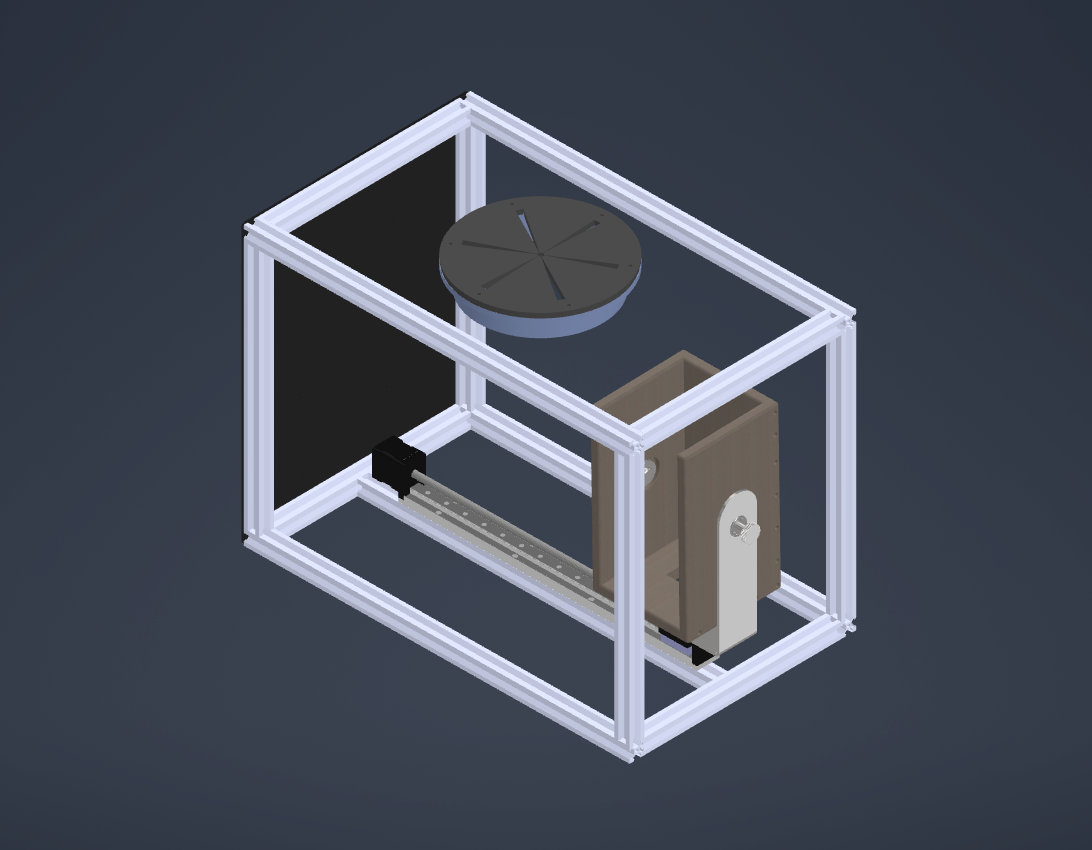

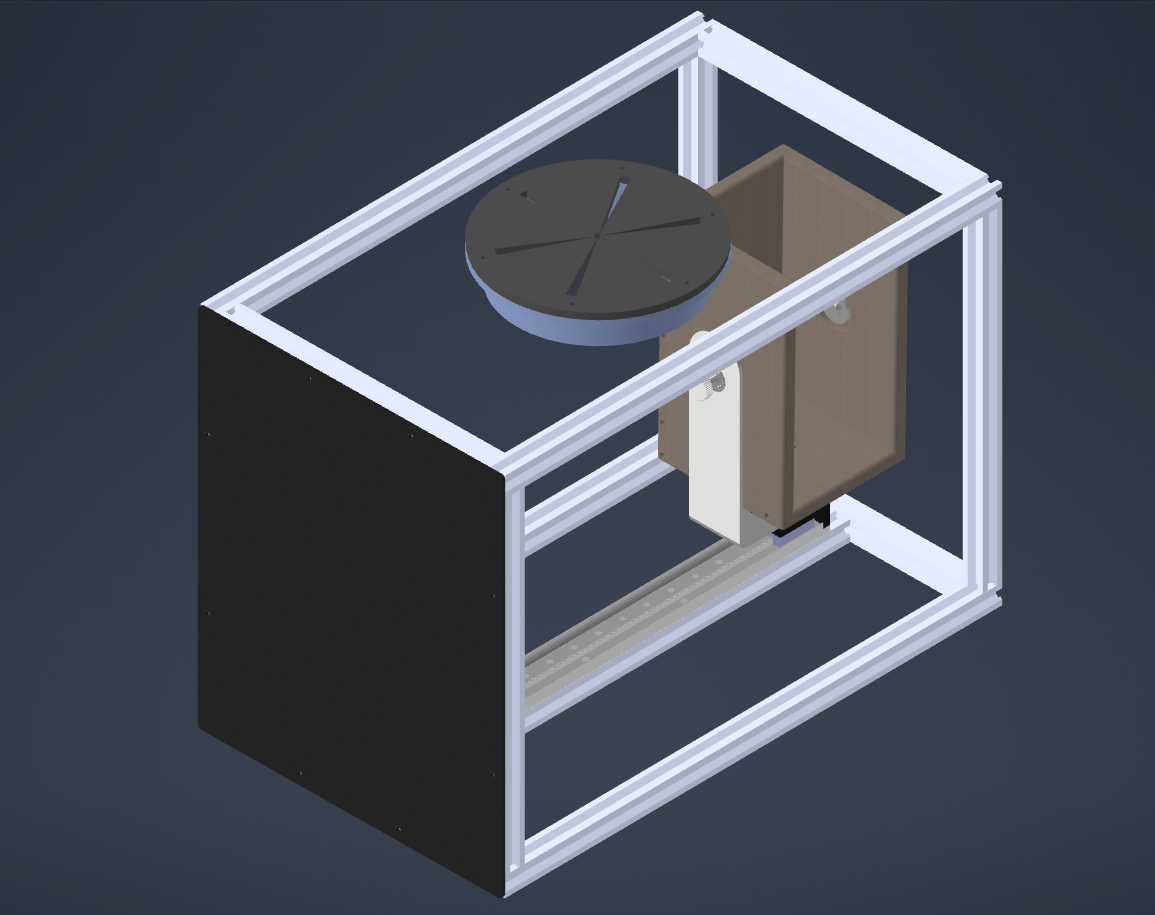

- Mechanical layout, CAD drawings, and iteration of the hopper, elevator, and tipper assemblies.

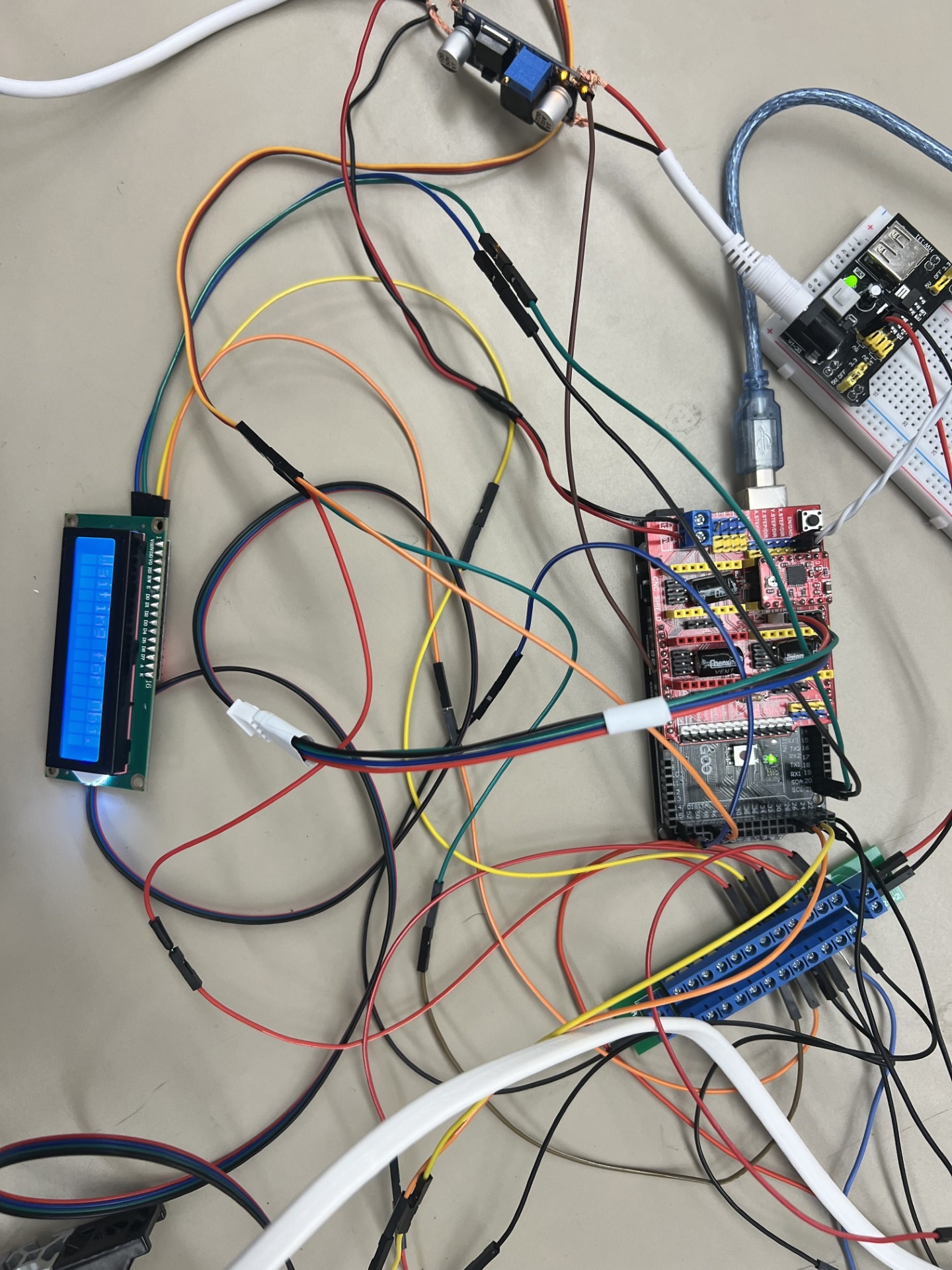

- Sensor selection/integration and microcontroller setup; wiring and bench testing.

- Assembly, troubleshooting, documentation, and demo preparation.

Outcome

- Working prototype demonstrating multi-material detection and actuation.

- Proposal + presentation package, system code scaffold, and manufacturing drawings.

- Targeting ≥95% sorting accuracy per design criteria.

Advised by course faculty • Fall 2024

Why this matters

Household recycling often fails due to contamination and inconvenience. Eco-Genie aims to reduce sorting effort and increase accuracy so more material actually gets recycled.

- Single-stream programs suffer from high contamination.

- Manual sorting is time-consuming and error-prone.

Targets

- Accuracy ≥ 95%

- Throughput ≥ 2 items/min

- Power < 50 W, Noise < 60 dB

- Safe, compact footprint; UL-minded design

Evaluated Architectures

- Design A: Optical + robot arms — accurate, but costly/complex.

- Design B: Rotary drum w/ embedded sensors — moderate accuracy, more maintenance.

- Design C (chosen): Ultrasonic + inductive + capacitive sensors; linear tipper & bucket elevator — best balance of cost, accuracy, throughput.

Decision matrix favored Design C across accuracy, speed, safety, and cost.

Architecture & Components

Concept to Prototype

The original concept sketch (from my build journal) guided the first CAD layout before parts were fabricated. Iterations focused on reliable flow through the hopper, robust elevator brackets/rollers, and a stiff tipper frame.

Selected Proposal Figures & Renders

Microcontroller Code (Excerpt)

Arduino scaffold for sensors and LCD (full code linked below):

// Initialization and Sensor Setup #include <Wire.h> #include <LiquidCrystal_I2C.h> LiquidCrystal_I2C lcd(0x27, 16, 2); const int trigPin = 26; const int echoPin = 28; const int capacitivePin = 24; const int inductivePin = 22;

// Ultrasonic Distance Measurement

long getUltrasonicDistance() {

digitalWrite(trigPin, LOW);

delayMicroseconds(2);

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

long duration = pulseIn(echoPin, HIGH);

return duration * 0.034 / 2;

}

// Material Detection Logic (simple heuristic)

String determineMaterial(int capacitiveCount, int inductiveCount) {

if (capacitiveCount > 25 && inductiveCount > 25) return "Aluminum";

else if (capacitiveCount > 25) return "Glass";

else return "Plastic";

}