James Riley Pacinda

Professional Summary

Mechanical Engineer (B.S., Texas Tech, 2024) who loves turning ambiguous problems into working hardware. I balance analysis and shop‑floor execution, planning experiments, running instruments, interpreting data, and iterating designs. Recent work includes undergraduate tribology research on PAO/ionic‑liquid systems with graphene‑oxide additives, plus sensor‑driven prototyping and simulation‑backed design.

My hands‑on experience started very early, from tearing down computers the moment I could take them apart, to swapping a minibike engine at 15 (and learning why chain guards matter), and building two 1/5‑scale 95cc fiberglass RC boats at 16. That tinkerer mindset still drives how I work: understand the physics, build it clean, measure it properly, and keep improving.

Highlights:

• RFW160 tribometer operation, SOP development, and repeatability studies

• Machining & sample prep (face cutting, polishing), surface characterization

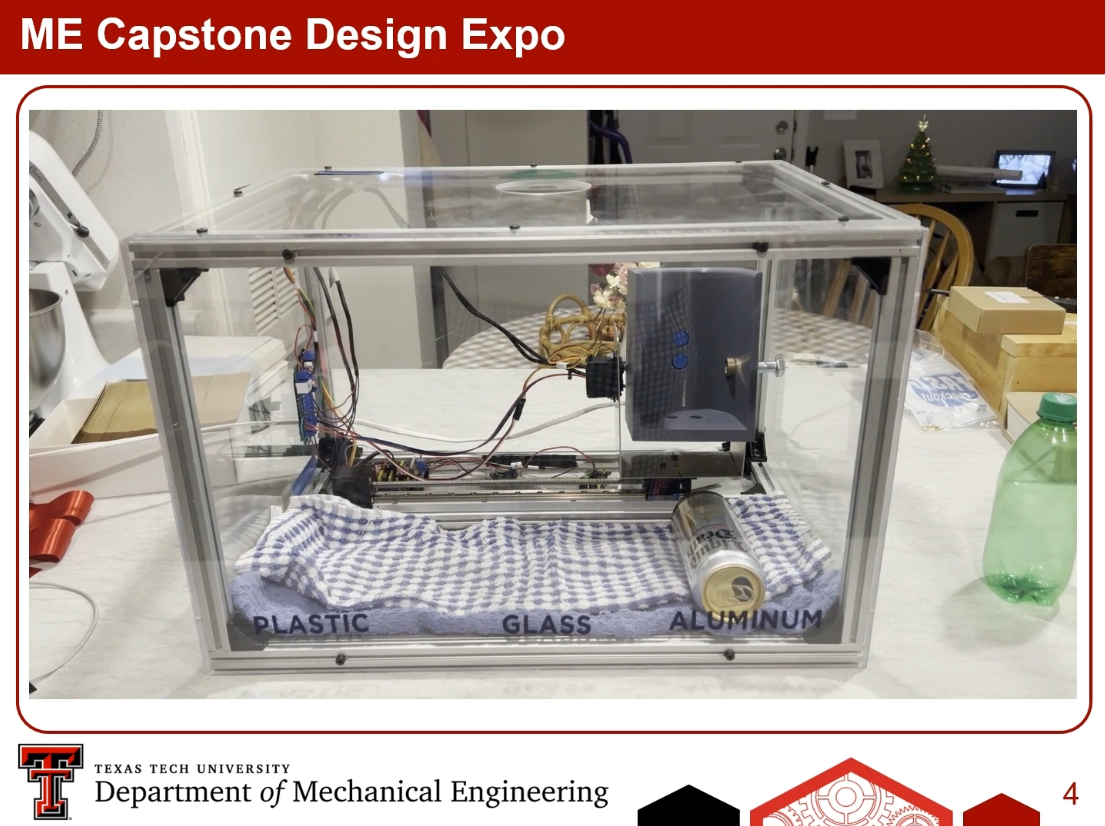

• Capstone: sensor‑driven sorting system from CAD to prototype (>95% accuracy)

• Clear documentation; collaborated with peers on ML models for tribological behavior

Technical stack:

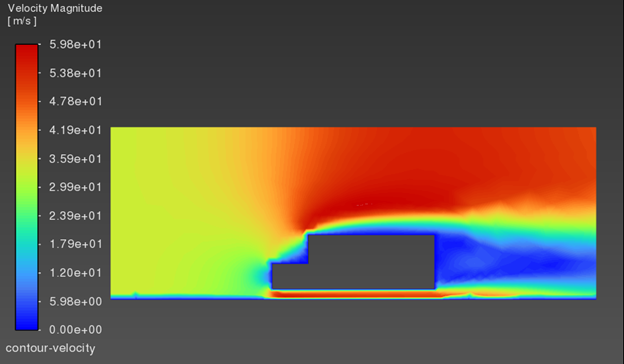

CAD: Inventor, SolidWorks, AutoCAD · Simulation: ANSYS (FEA/CFD), MATLAB · Programming: Python, LabVIEW, C++, Arduino ·

Prototyping: 3D printing, machining, fabrication, wiring/control systems ·

Lab: tribology, microhardness, calibration, diagnostics, failure analysis, thermal imaging ·

Tools: multimeters, soldering, SEM

.png)